![]()

| Increase profits, decrease cost. |

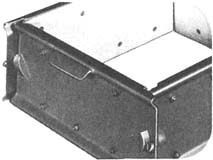

| All Wopper Jaw Slip Jackets are manufactured of specially formed steel channels, angles or plates in widths from 4" to 24" in 1 inch increments, and from 28" to 200" perimeter. Jackets conform perfectly to parting lines and taper. Standard Jacket styles can be tailored to your specific needs. Angle iron reinforcing, for greater strength, is available on sides and ends upon request. Your choice of corner construction for the type of performance needed, and the choice of handles make this the most versatile line of jackets available. |

|

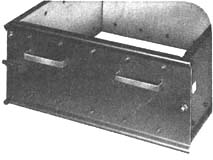

STYLE 1 Standard Wopper Jaw Slip Jacket. Made of specially formed 3/16" thick steel channel. Cope flange is used as handle for shifting jacket. STYLE 1 A Same as Style 1, except made of 1/4" thick steel channel for heavy duty. |

|

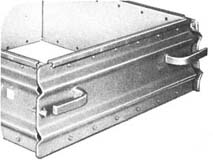

STYLE 2 Made of 1/4" thick steel specially formed angles with 5" open steel channels for easy handling. No flange on cope side to reduce weight. |

|

STYLE 3 Made of 1/4" thick steel specially formed angles with flange on cope side, which also acts as a handle. This jacket is widely used on conveyor systems and where space is a factor. |

|

STYLE 4 Specially formed 10 Gauge Steel, lined with 1/4" thick Transite to provide heat resistance and lightest weight. Angle handles for ease in shifting. STYLE 4-S Same as type 4 except Transite liner is 1/2" thick to provide maximum heat resistance at the narrow depth levels for 6" Jackets and above. |

|

STYLE 4-P Made of 10 gauge steel lined with 1/4" thick Transite. Liner protection on both top and bottom, increased strength, with this one piece side construction. STYLE 4-P-S Same as type 4-P except Transite liner is 1/2" thick to provide maximum heat resistance at the narrow depth levels for 5" and 6" jackets. |

|

STYLE 5 Heavy Duty Jacket of specially formed 3/16" thick steel with 1/2" thick Transite Liners for maximum service. Four (4) 1/2" x 1" steel handles are provided for 2 man shifting to pipe handles for use with hoists. No jacket job is too tough for the Type 5 Wopper Jaw Slip Jacket. |

|

STYLE 6 Economy 6 is made of 10 gauge flat steel sides and ends, half oval corner construction, and with angle handles 1" x 1/2" x 4" long. Where weight was a problem, this jacket has proven to be very successful. Angle Iron Reinforcing is available on all models upon request. |

|

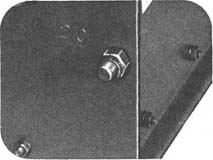

ROUGH DUTY CORNER CONSTRUCTION Greater bearing area provides greater resistance to wear. Increased strength enables Jackets to withstand greater abuse, while still maintaining accuracy. Easier to disassemble and reassemble when straightening or when replacement of side becomes necessary. Also available in adjustable Jacket. |

|

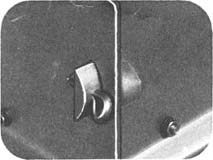

HEAVY DUTY CORNER CONSTRUCTION Standard on all Jackets unless otherwise specified. 3/8" stud up to 9" in depth Jacket. 1/2" |

|

LOCK STUD CORNER CONSTRUCTION For the fine adjustment that enables Jacket to move up or down in cope or drag. 1/2" stud can be moved by use of wrench |

|

BAR HANDLES Four (4) each on side or end for two man shift. PIPE HANDLES For use with hoists. Available upon request. |

|

CHANNEL HANDLES For one or two man shift . . . one on each end (one man shift) ... two on each end (two man shift). |

|

ANGLE HANDLES For one man shift. Custom Corners and Handles also available. |